The reliability of data is very important for the interface of computer system. Whether it is network cable, USB or SATA protocol, when receiving the uncorrectable error, the sender will be required to retransmit the data that has not been received correctly. However, this is not applicable to HDMI interface mainly used for consumer electronics. If HDMI also adopts this method, in the case of slightly heavy error code, the sender will be required to retransmit the data that has not been received correctly, Obviously, it will cause frequent pauses of video or audio, which should be unacceptable to most people. Therefore, HDMI's practice is the common practice of streaming media. It doesn't matter if the audio and video data is transmitted to the receiving end. In this case, HDMI can't do anything about the errors in the data transmission process? The answer is No. HDMI uses an error correction code called BCH ECC. Every 56 bits of data is equipped with 8 bits of check code. The sender calculates 56 bits of data with a specific algorithm to get 8 bits of check code. After receiving the code, the receiver calculates 56 bits of data and 8 bits of check code with the corresponding decoding algorithm. If the two sides can't correspond, The a0412 bit error meter and bit error test system in the figure below is an efficient and convenient test instrument and system for AOC module factory and (HDMI / USB / DP...) cable manufacturer to test and analyze product quality independently developed by Shenzhen xingxinding Technology Co., Ltd. with independent intellectual property rights. A0412 is a high-performance, low-cost, easy to operate, function rich 4-channel parallel 12g high-speed code stream generator and analysis equipment.

This product is specially developed for the online test application of video high-speed cable (HDMI / USB / DP...), and is a necessary equipment for testing and producing high-speed cable. The instrument can be operated independently and also connected with PC software, which can simulate most of the application equipment in the market, making the production more concise, convenient and professional. With the special bit error operating system, the product supports engineer debugging interface and production line test interface, supports comprehensive engineering analysis and mass production data collection, and meets the application requirements of various scenarios. A0412 adopts high reliability anti fool high-speed interface, users can change the corresponding interface test board according to the type of products to be tested, compatible with HDMI / DP / USB / type-C and other application interfaces.

The performance characteristics of this bit error detector

1. Four channel synchronous output, 12g output for each channel, used to test 48g products, bit error test can be independent or four channel synchronous test.

2. Support continuous error detection and timing error monitoring.

3. Support rate: such as 3.4g, 5g, 6G, 8.1G, 10g, 12g, etc

4. Supported code types: prbs7, prbs9, prbs15, prbs23, prbs31, user pattern

5. High density connector is used to connect with test board.

6. Communication mode: USB to hid. Through the communication between PC software and the device, set the bit error meter and test the bit error rate, drive free hid.

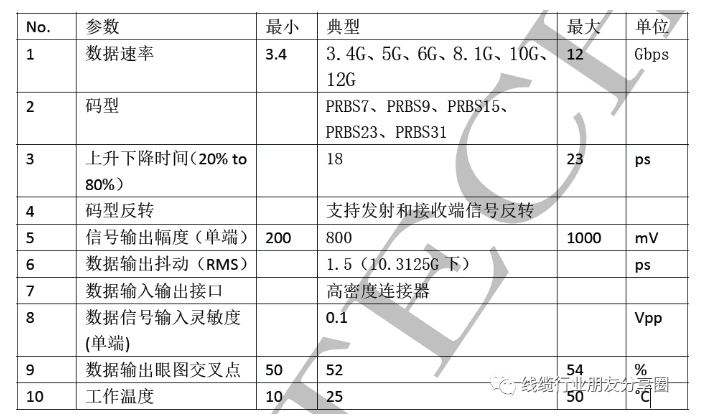

Description of technical parameters of this bit error detector

此误码仪电眼图实测

This bit error tester has a PC test interface

The application scenario of this bit error detector

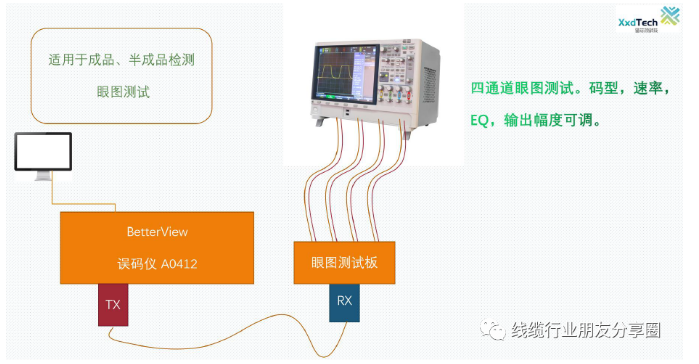

Standard or custom signal output eye diagram test

The a0412 bit error detector we introduced today can be compatible with any form of product interface, such as HDMI, DP, USB, type-C, etc. the bit error detector can simulate and replace the vast majority of devices on the market for test interception, eliminating the import of compatible devices with different requirements of each customer, and supporting customer's software and hardware customization requirements.